Aluminum Alloys

In our 100-year history, we've forged many materials, and we currently specialize in forging high-strength, lightweight aluminum precision products. We provide 100% domestic material sourcing and work in partnership with our suppliers to offer the best lead times in the industry for the key raw materials used to forge your aluminum component.

Anchor Harvey offers several types of forged aluminum alloys for a host of applications from aluminum-alloy wheels and specialized defense components to aircraft-grade aluminum parts. Our aluminum alloy components are most commonly forged from 2000 Series Aluminum, 6000 Series Aluminum, or 7000 Series Aluminum.

COMMON ALUMINUM ALLOYS

7000 Series Aluminum Alloy

(Aluminum 7075-T6; 7075-T651)

Aluminum in the 7000 series is alloyed with zinc to produce the strongest aluminum alloy. Alloys in this series, such as 7075 aluminum, are used for highly stressed structural parts and can be tempered to offer improved stress corrosion and cracking resistance. 7000 series aluminum alloys are commonly used in aerospace, structural, and defense applications.

Common Applications We Forge Include:

- Aircraft Fittings

- Missile Components

- Bike Frames

- Actuators

- Aerospace And Defense Applications

- All-Terrain Vehicle Suspensions

- Fuse Parts

- Regulating Valve Parts

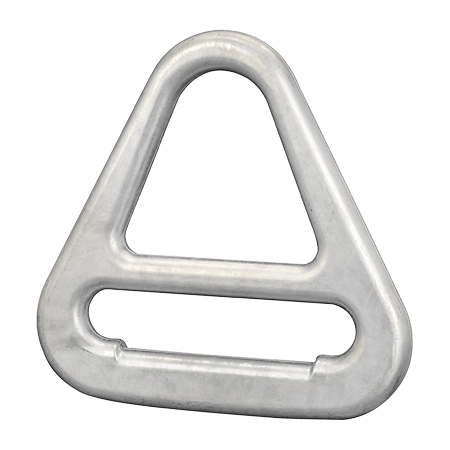

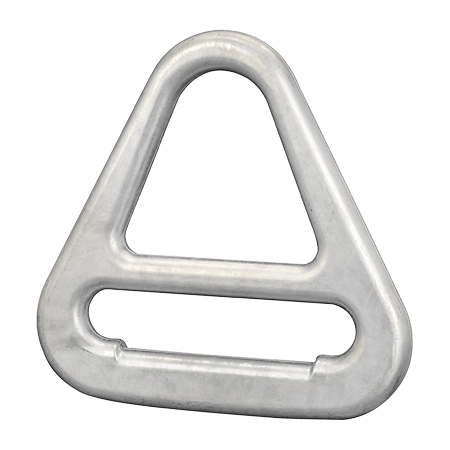

6000 Series Aluminum Alloy

(Aluminum 6061-T6; 6061-T651)

The 6000 series alloys combine aluminum, magnesium, and silicon to provide relatively high strength while maintaining a substantial degree of workability with excellent joining characteristics and an exceptional acceptance of applied coatings. Alloys in the 6000 series, such as 6061 aluminum, are among the superior aluminum alloys for use in applications that may require spot welding, fusing, or anodization to provide increased resistance to corrosion.

Common Applications We Forge Include:

- Aircraft Fittings

- Marine Fittings And Hardware

- Electrical Fittings And Connectors

- Brake Pistons

- Hydraulic Pistons

- Couplings

- Miscellaneous Hardware

- Valves and Valve Parts

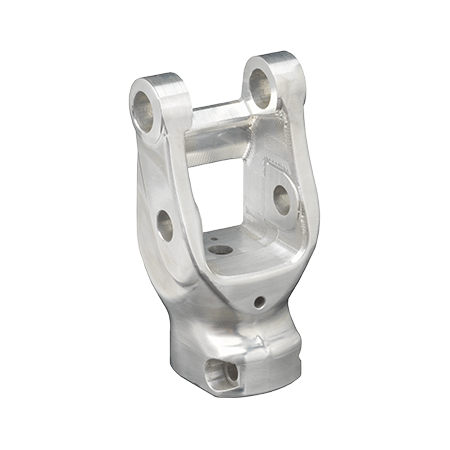

2000 Series Aluminum Alloy

(Aluminum 2014-T6; 2014-T651)

The 2000 series of aluminum alloys, including alloys such as 2014 aluminum, are "hard alloys" that are commonly used in applications requiring a higher degree of strength or use in elevated temperatures. 2000 series aluminum is alloyed with between 2 and 10% copper to facilitate substantial increases in age hardening and strength. The introduction of copper to aluminum can reduce ductility and corrosion resistance but result in some of the highest strength, heat-treatable aluminum alloy components available.

Common Applications We Forge Include:

- Heavy-Duty Forgings

- Structural Components

- Aerospace Spars

- Automotive Frames

- Suspension Components

Contact Us to Learn More